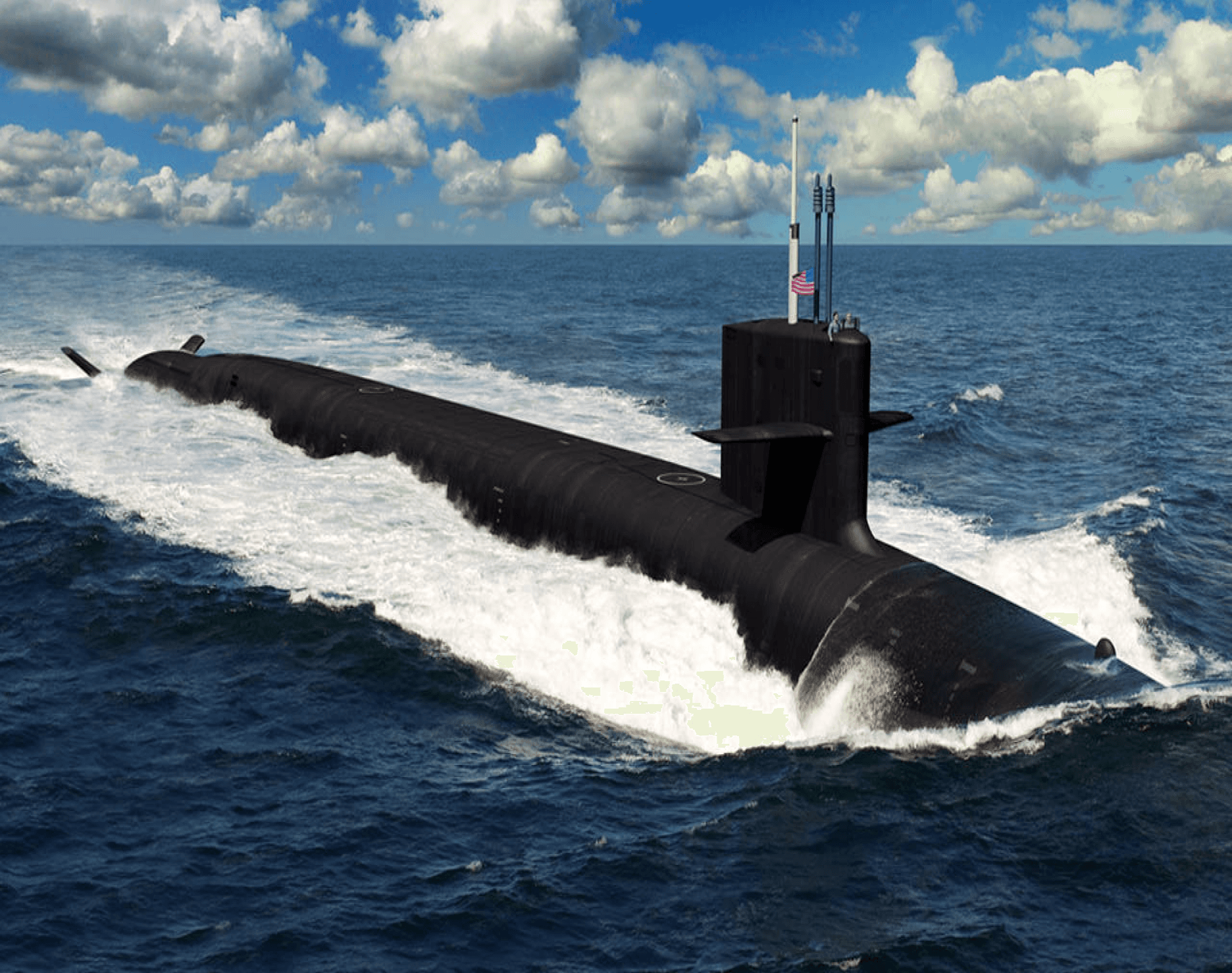

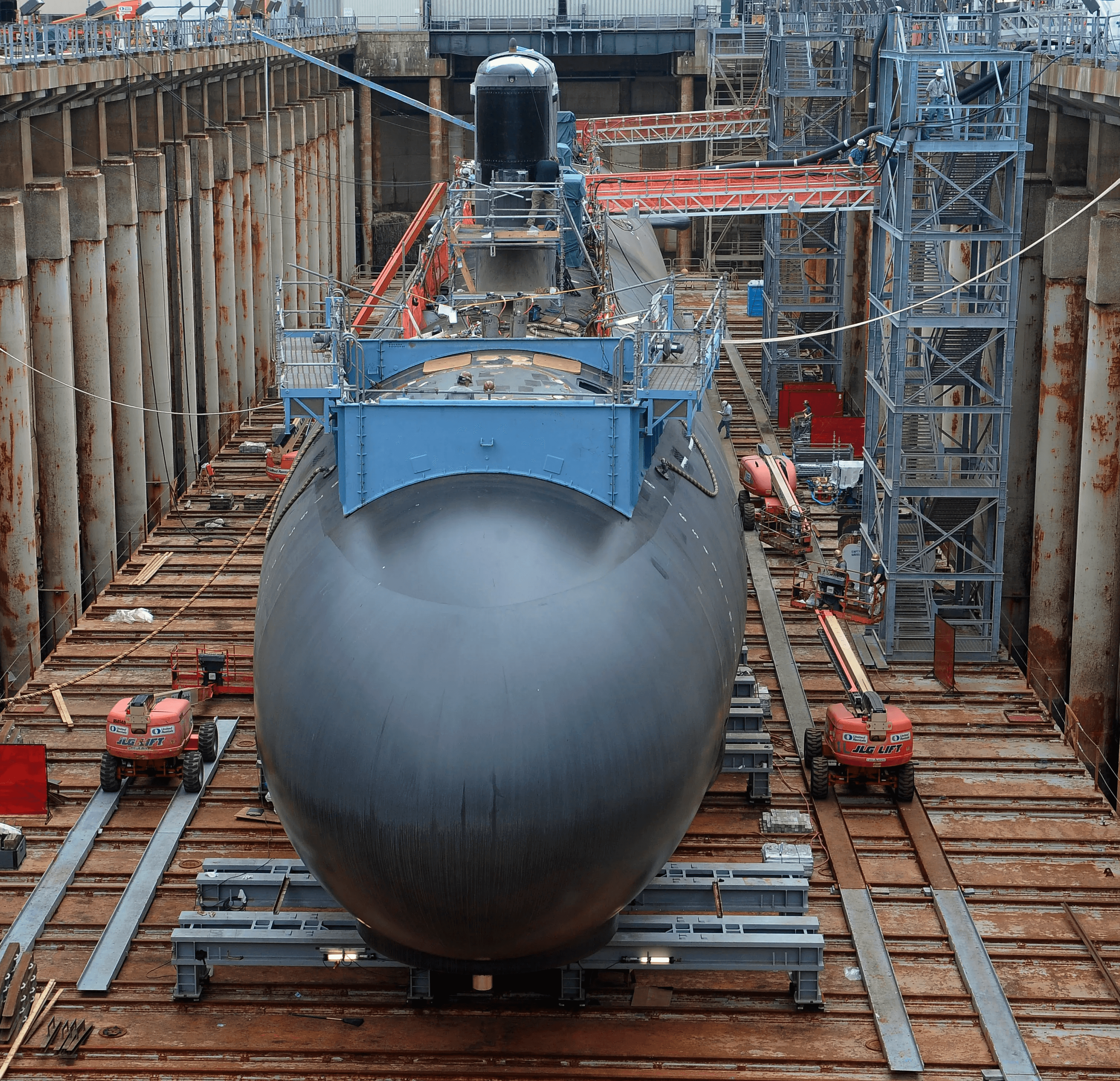

This summer I helped automate the construction of the biggest nuclear submarine in history. I created hundreds of optimized nests, led a variety of independent process improvements, and developed programs to support Lean Six-Sigma frameworks.

Key Outcomes

Designed and optimized nests for Nuclear Submarines to aid Lot-Based Manufacturing of VPM/CLB-class hulls

Utilized VBA to construct database integrations for Polyethylene, Steel, and Sheet Metal process automations

Applied Lean Six Sigma frameworks to reduce construction span-times by more than 120+ hours per hull per year